Product Description

1.Construction

The machine consisted of electrical control system,mixing head,chemical tanks,metering pumps,frequency converter,control and adjust system of temperature,rotate speed and pressure,cleaning system,air push system and base frame etc.

2.Feature

*Adopt rotary valve type three-cylinder,prevent blocking of casting hole and cleaning hole.Isochronous operation of casting and mixing ensure the quality of product.

*Adopt high precision metering and frequency converter,variable frequency speed regulation,stable operation,easy to use.

*Adopt microcomputer controller to set and adjust data of casting,clean and air push works.Display and adjust data of temperature,pressure from data display instruments,temperature error ≤2℃.

3.Main parameters

NO. | Model | Output(KG/MIN) | Volume of tank(L) | Power(KW) | Appearance(mm) |

| 1 | PU20D-Y1 | 1.5-4 | 120~160~220 (Optional) | 9 | 1500*1160*2060 |

| 2 | PU20D-Y2 | 4-12 | 9 | 1500*1160*2060 | |

| 3 | PU20D-Y3 | 8-20 | 10.5 | 1500*1160*2060 | |

| 4 | PU20D-Y4 | 15-40 | 12 | 1500*1300*2120 | |

| 5 | PU20D-Y5 | 20-60 | 12 | 1500*1300*2120 | |

| 6 | PU20D-Y6 | 30-80 | 13.5 | 1500*1300*2120 | |

| 7 | PU20D-Y7 | 40-120 | 17 | 1500*1300*2120 | |

| 8 | PU20D-Y8 | 60-160 | 20.5 | 1500*1300*2120 | |

| 9 | PU20D-Y9 | 80-200 | 20.5 | 1500*1300*2120 |

4.Application

Used to produce flexible high resilience,slow rebound,integral skin and rigid foam.

Such as cushions of sofa,motorcycle,bike and auto,armrest,imitation wood furniture,steering wheel and some insulation board etc.

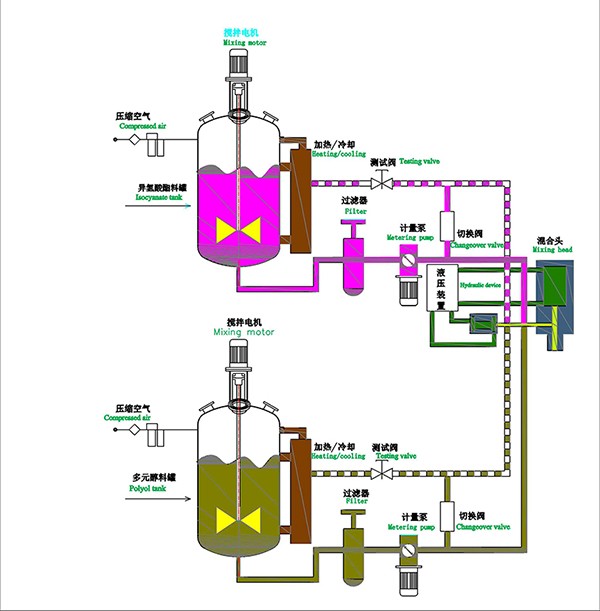

Flow Chart

Packaging & Shipping

1.Export standard plywood cases for better care when transport;

2.Ocean shipping, air transportation or land transportation for choices.

Our Services

1.Free to visit, introduce, do Selection Guide;

2. Free to visit home clients to know in-service condition of machine;

3. Test and adapt whole setting data here as according clients’demands;

4. Send experienced engineers to guide installation, operation, debugging and maintain;

5. Rich supporting suppliers of molds, chemical and others for reference.

FAQ

1. Application field: Manufacture various PU foam mattress, cushion, acoustic insulating material, backrest, sofa, memory pillow, PU foam tires, self skinning foam arm rest, integral skin foam bumper and toys etc;

2. Chemical material: polyol and isocyanate;

3. Components and capacities: 2 or 3 even more components, 87-435g/s, 160-800g/s, 375-1875g/s, 750-3750g/soutput etc;

4. Temperature types: Normal temperature;

5. Multicolor products manufacture: additional color paste adding systems selectable.

Quick Details

Processing Type: Foaming Machine

Condition: New

Product Type: Foam Net

Place of Origin: China (Mainland)

Brand Name: EMM

Voltage: 380V

Power(W): 30KW

Dimension(L*W*H):1.6mx1.4mx1.5m

Weight: 1200kg

Certification: CE

Warranty: One Year

After-sales Service Provided: Engineers available to service machinery overseas

Name: PU Foam machine

Product Name: PU Foam machine

Type:Low Pressure PU Foam Machine

Automatic: Auto Foam Machine

Raw material: POLY and ISO

Control System: PLC+Touch Screen

Feature: High Efficiency

Item: PU20D

Application:PU Panel;fire room ect.

Special: High Efficiency Foam Machine