Brief description

The technology we used is from Germany. We can provide you top level machines with competitive price and perfect services. We are integrated with design, R&D, production, marketing, and after-sales services.

Quick Details

Place of Origin: China (Mainland)

Brand Name: EMM

Model Number: DM-402

After-sales Service Provided: Engineers available to service machinery overseas

Type: FIPFG formed in place foam gasket manufacturing

Strip width: Micro type: 2-8mm; Standard type: 5-30mm

Technology: Mixing head designed and manufactured in Germany

Dosing system: Barmag metering pump

Control system: Taiwan Syntec CNC system with hand controller

Driving system: Panasonic servo motor

Cleaning system: Water rinsing, built-in the mixing head.

Working speed: 0-12m/s, usually be 6-10m/s

Raw material: Polyurethane, PU, Silicon, other liquid material

Certifications: CE, ISO, RoHS, SGS, CQC, etc.

Product Description

2 components EMM automatic PU foam sealing gasket making manufacturing machine

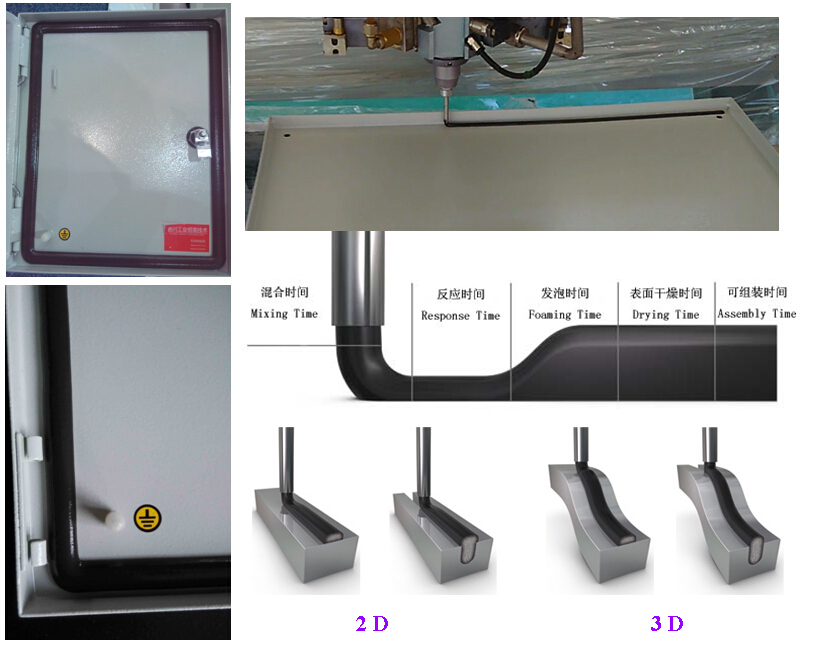

This machine can mix two kinds of raw material together and pour to pre-set position, groove, mould, or the flat surface of workpiece etc directly. Through chemical reaction, the liquid raw materials form elastic sealing strip in seconds. There is no joint or cut point, so comparing with other kind of sealing its effect is much better and with longer using life. And, during the forming process, the sealing strip surface become very smooth and without any crack, so its sealing effect is perfect. And, because it can stick on the workpiece naturally and tightly, no gluing worker is needed, huge cost is saved from labor and time, etc.

Foam sealing equipment is used more and more in sealing fields like controlling cabinets, lighting, motor vehicle, machining industry, etc. It is leak proof, oil proof, water proof, damping, noise proof, and sealing, etc. It is in accordance with certifications like UL/CE, MIL-STD-167, EN50298, and so on.

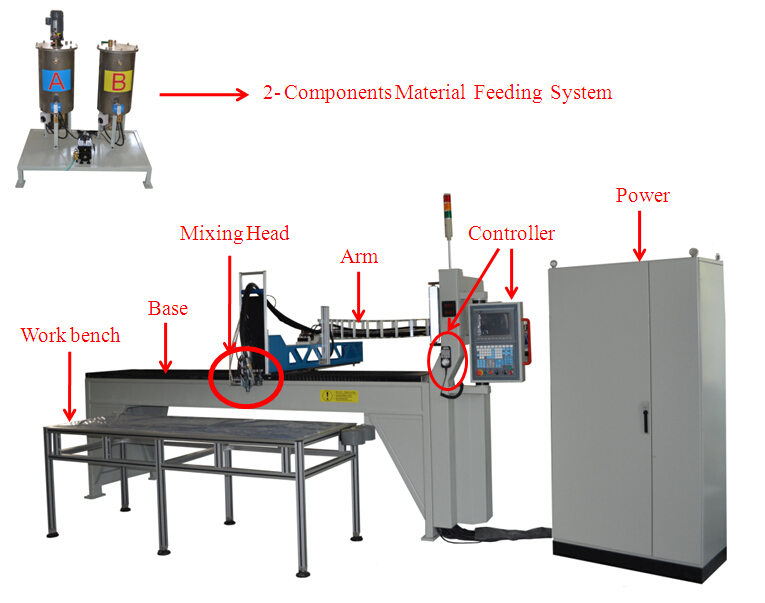

Gasket making machine Construction:

Gasket making machine Raw Material Reaction Principle:

Gasket making machine Main Parts

1. Mixing Head:

Water Rinsing & Modular Design

2- / 3- component mixing head with high-pressure water rinsing system and dynamic mixing system, for use with liquid to high-viscous polymer reaction materials for gasketing, gluing and potting.

2. Operation System:

CNC System from SYNTEC, 180 degree rotating freely, Multi-language selection, Storing huge frequently-used information, Plus USB interface and G-code program, Manual operation is for choice also, Can be operated simply.

3. Raw Material Barrels:

Double walled stainless steel, control temperature automatically.

4. Work bench:

Aluminum alloy, strong and durable.

5. Dosing System:

Barmag metering pump, Panasonic servo motor, Microscale gluing is workable.

6. Hand Controller:

SYNTEC made, easily control, response quick and steady.

7. Driving system:

Panasonic servo motor, work steady, long using life, can keep working for dozens of hours.

Our Gasket making Machine Equipment Advantage:

| Our Company, Jinjie | Some other companies | |

| Technology | From German, top level, mature and stable | R&D in China, Chinese level, in developing |

| Mixing Head | Made in Germany (Germany manufacturing and processing technology, and quality) | Made in China, Chinese quality. |

| Working Mode | 2D or 3D for choice (could process special 3D patterns) | 2D only |

| Control Mode | 8 axis linkage as a whole (1X+1Y+1Z+2Mixing+2Reserved, Could adjust & change to 3-components equipment or adding auto material feeding system according to needed.) | 3 axis + other control systems, need matching |

| Gluing Width (Standard type) | 5-30mm | 8-30mm |

| Gluing Width (Micro- type) | 2-8mm | 3-8mm |

| Repeat Positioning Accuracy | +/-0.03mm | +/-0.05mm |

| Dosing | 0.5~5g/s | 1~4g/s |

| Continous working time | can keep working for a whole day (there is a special coating on the mixing head to prevent residual) | Frequently temporarily stop for cleaning residual |

| Processing capability of factory | machine shop belongs to ourselves, Jinjie | Processed by another company, then assembled in another place. |

| Offer | Very competitive | Higher |

Gasket making machine Standard type equipment specifications:

| Technical Specifications | Some Other details | |||

| Mechanical Arm | 6*3 m | Technology | From Germany | |

| Workbench | 2.4*0.9 m | Mixing Head | From Germany | |

| Material Bench | 1.2*0.85 m | Operation | From Taiwan Syntec, CNC system | |

| Working Stroke | 2.4*1.2*0.25 m | Hand Controller | From Taiwan Syntec | |

| Gluing Width | 5-30 mm | Motor | Panasonic Servo Motor | |

| Gluing Precision | 0.01 mm | Metering Pump | From Germany, Barmag | |

| Working Speed | 0-12 m/min | Cleaning | Water Risining | |

| Max Speed | 30 m/min | Material Barrels | Double walled stainless steel, control temperature automatically | |

| Repeat Positioning Accuracy | +/- 0.03 mm | Control Mode | 8 axis linkage, 1X+1Y+1Z+1mixing+2metering+2reserving | |

| Dosing | 0.5-5 g/s | Working Mode | 2D or 3D | |

| Filling Accuracy | 0.1 g/s | Main Color | Silver gray, refer to picture, or black, red, ect. under discussing. | |

| Mixing Speed | 0-3000 rad/min | Custom-made, OEM, ODM | OK, no problem. | |

| Mixing Ratio | 1:10~10:1 Adjustable | Certifications | CE, RoHS, ISO, etc. | |